Chemical Injection Valves

Chemical Injection Valves

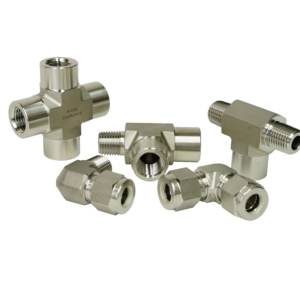

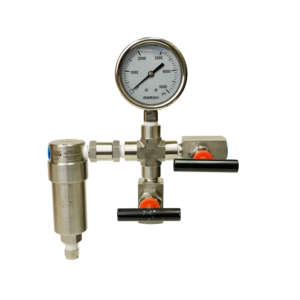

Republic Oil Tools is a leading manufacturer of check valves for use in chemical injection systems for upstream oil and gas operations. The Republic product line of check valves, called TruCheck™, eliminates internal o-rings, elastomers, and the removable seat to ensure the tools truly check to keep wellbore fluid from entering and plugging the capillary string. Additionally, the top compression fitting where the check valve connects to the capillary tube will never be a ball seat thereby eliminating field service from dropping parts downhole while making up the check valve. The TruCheck Injection Valve (TCIV) product line has several different tiers to ensure a reliable, cost-effective solution.

Some of the common applications where Republic’s check valves have been deployed successfully include:

- Corrosion Inhibitors: These are used to prevent corrosion of well equipment and pipelines by reducing the corrosion rate and increasing the service life of the equipment.

- Scale Inhibitors: These are used to prevent scaling caused by mineral buildup in the well. They help maintain the flow of fluids through the well by dissolving or preventing the formation of scale deposits.

- Biocides: These are used to control the growth of microorganisms in the well that can cause production problems, such as reducing the permeability of the reservoir or corroding the downhole equipment.

- Surfactants: These are used to reduce the surface tension of the fluid in the well, making it easier for the fluid to flow through the well and into the production tubing.

- Demulsifiers: These are used to break down oil-water emulsions in the well, allowing the oil and water to separate and improving the efficiency of the well.

Regardless of application, Republic Oil Tools’ portfolio of chemical injection valves provides superior protection to keep the capillary string from plugging. This eliminates downtime and promotes efficient and economical production as compared to legacy chemical injection valves.

NEED ASSISTANCE?

We have a dedicated staff available to answer your questions and help you find exactly what you're looking for.

432-201-1180